Established in 2008 we have more than 10 years rich experiences in cap compression molding machine as the pioneer of cap compression molding machine in china we have wined the certifications of ul iso9001 2015 and other 100 national patents like state torch project state innovation foundation project etc.

Cap compression molding machine taiwan.

Multiplas is the injection molding machine manufacturer has established an excellent reputation in the worldwide markets for the dependability of its injection molding machines.

Low melting temperature means energy saving and low cap cost.

Machine is easier and quicker to manage.

Reduced and easier machine maintenance.

An effective control of the production repeatability.

Multiplas might be your best partner injection molding machine manufacturer in the future.

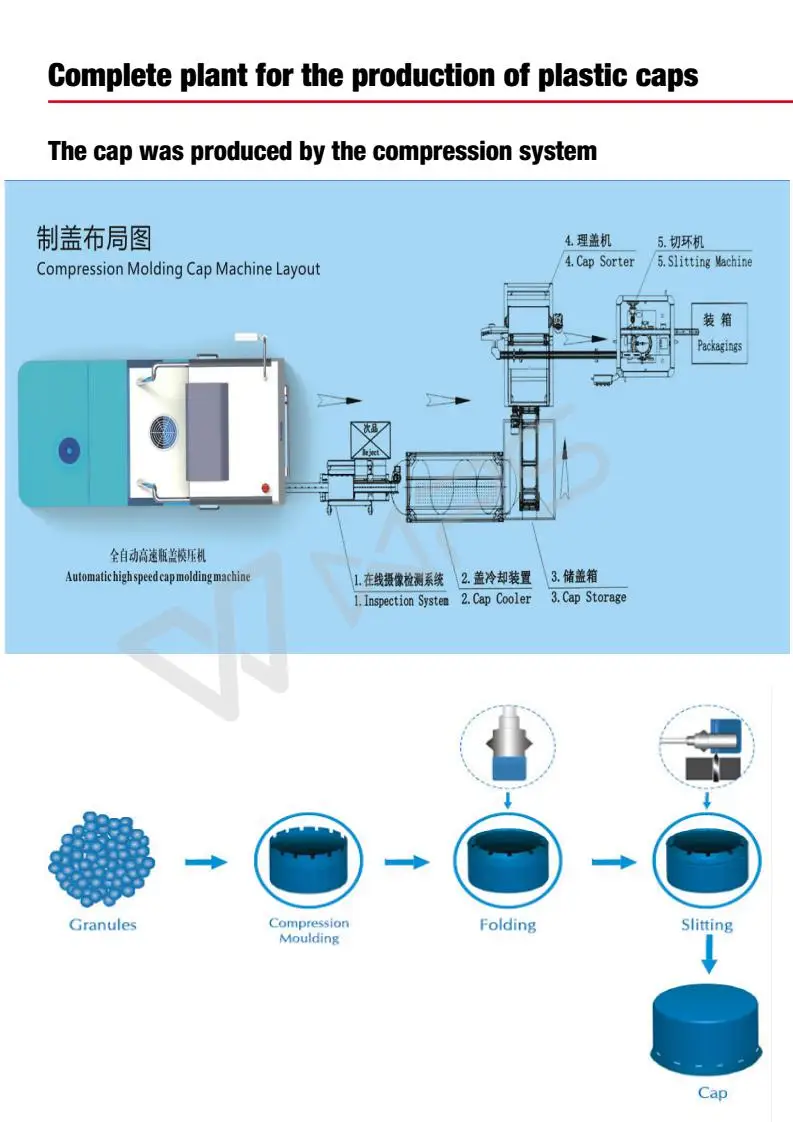

Zq c24h high speed plastic cap compression molding machine is applicable for cap production from thermoforming plastics pp pe etc its rotating design e.

The cap production is much faster and of even quality and the power consumption is also much lesser than an injection molding machine.

Caps made by compression molding have better geometrical features and are more consistent compared to the injection process and allow the user to employ a wider range of raw materials.

Adjustable daylight accommodates different height of molds.

Taizhou ouming packaging machinery technology co ltd is a professional china products suppliers and products wholesalers which is a high tech enterprise with more than 20 years of production experience specializing in the research development design and manufacture of bottle cap machinery is located in mold town of china huangyan the products manufactured by the company is widely used.

We have provided customers in injection molding machinery performance quality and price welcome your inquiry.

Longer efficiency periods of the machine.

About 9 of these are capping machines 1 are other plastic product making machinery.

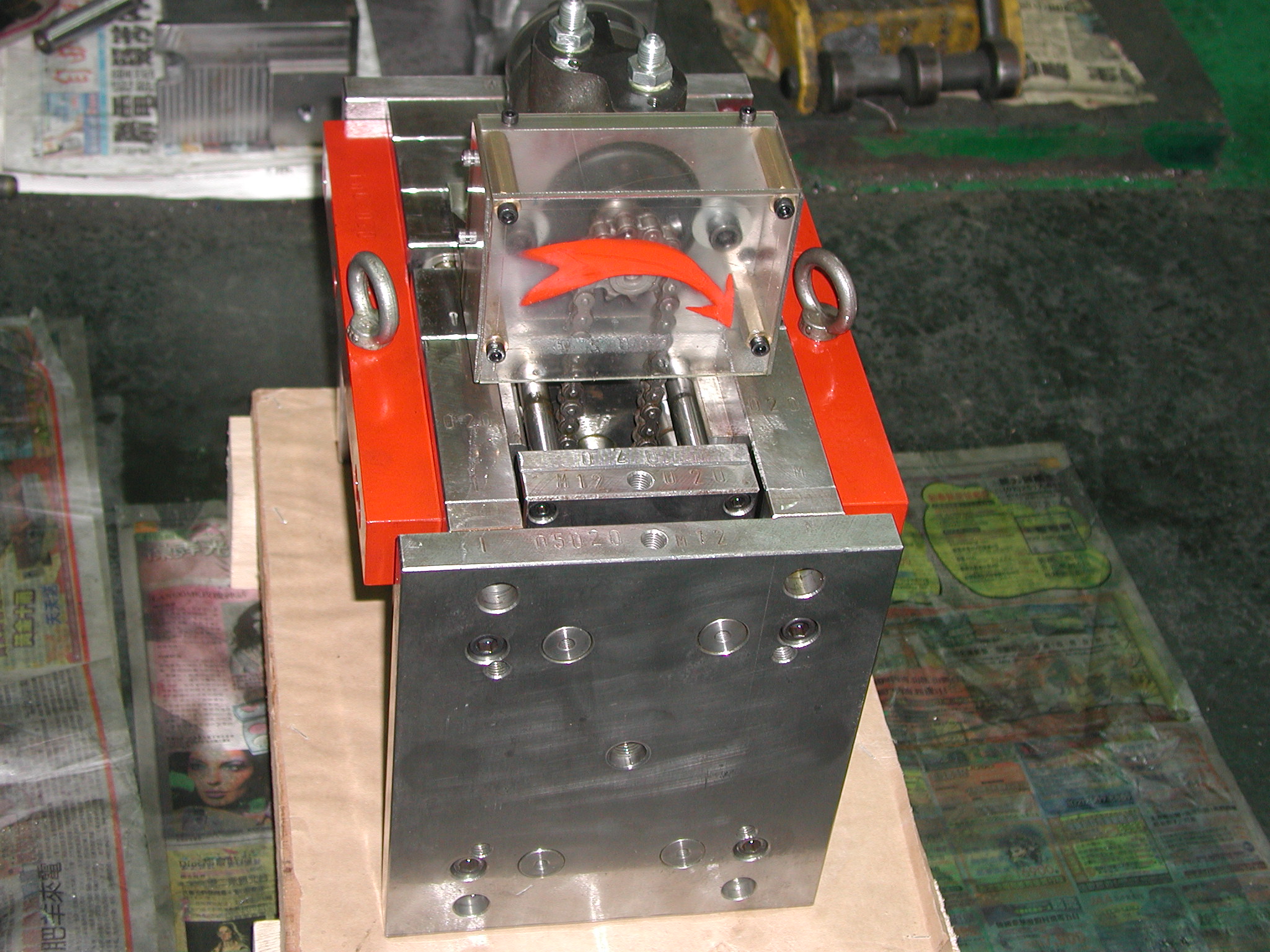

Hydraulic plastic cap compression molding machineis used to making the particles of plastic to the bottle caps of carbonated beverage and mineral water by high temperature plasticizing when the plastic was out of the extruder the blanking plate will cut the embryond putting them into the moulding chamber uniformly the bottle cap making by this type of machine will be without injection gate.

Why compression is the best choice for cap.

Rotary cap compression machine quality of cap produced on rotary hydraulic compression machine has received wide acceptance from customers because of its quality and finish and has fetched a higher selling price then the ones produced using injection moulding process.

A wide variety of plastic cap compression molding machine options are available to you such as condition local service location and key selling points.

.jpg)